Product Update Highlights: Clarifresh Quarterly Webinar Recap

- Quality Control App

From defect photos to dashboard exports, this quarter’s updates are all about control. Whether you’re overseeing thousands of inspections or just trying to keep your suppliers aligned, we’ve rolled out new tools to help you work faster, communicate better, and reduce the guesswork.

Here’s a full breakdown of the new features and what they mean for you.

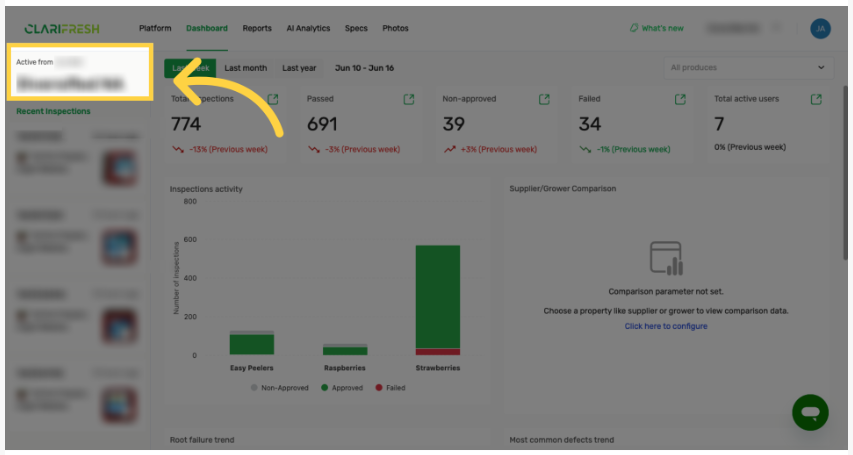

A smarter, more actionable dashboard experience

The Clarifresh dashboard has been redesigned to make your first stop the most valuable one. Whether you’re scanning inspection trends or digging into the root cause of failures, the new layout surfaces the most important KPIs instantly, so you can act fast and stay in control.

What’s New in the Dashboard Experience:

- Key Metrics, Front and Center: Instantly view total inspections, approval status, pass/fail breakdowns, and total active users, all compared to previous periods for easy trend spotting.

- Interactive KPI Cards: Click any card to go straight to the relevant filtered report. Inspection stats link to Reports; the user card links to the Usage Report.

- Inspection Activity Chart: Visualize the volume and outcome of inspections by produce type, segmented by approval and grade status (e.g., Non-Approved, Approved & Passed, Approved & Failed).

- Custom Comparison Chart: Easily compare performance by grower, supplier, country of origin, or any custom property. (Set your preferred grouping via Company Settings > Supplier dropdown.)

- Failure & Defect Trends: Track the top 5 causes of inspection failures and most common defects across a selected time period.

- Filters for Faster Insights: Narrow your dashboard view by time period (week, month, year) and produce type.

- Sub-Account Summary Table: Get a quick breakdown of inspection data by sub-account and commodity, with links to each report.

- Frequent Data Refresh: Dashboard metrics update every 10 minutes to reflect the latest inspections.

For a full breakdown of dashboard features and configuration options, see our Help Center article on the updated dashboard.

Sharing specs securely with growers and partners

Getting growers or partners to follow your quality specs shouldn’t require constant back-and-forth. With Clarifresh’s new secure sharing options, you can now share inspection specs privately, making collaboration easier while maintaining full control over your standards.

What’s New:

- Private Sharing via Unique ID: Share specific spec templates with external accounts by sending them your unique ID. Specs stay private.

- External Spec Adoption: Partners can apply your shared specs directly within their own Clarifresh account, streamlining setup and alignment.

- Edit Restrictions: External specs are read-only for receiving accounts to ensure consistency. For broader collaboration, sub-accounts remain the recommended method.

- Import & Copy Options: Receiving accounts can also choose to copy shared specs into their own workspace for customization (note: copied specs aren’t linked to the original).

Shared specs provide a controlled, flexible way to ensure everyone is working from the same page, without giving up ownership or oversight.

See our Help Center article on sharing specs by unique ID

Smart QC reports with clear grading logic

Our upgraded Smart QC reports make the reasoning behind each grade completely transparent, even for external stakeholders. Smart QC reports now explain the exact logic behind each grade, so everyone stays on the same page.

What’s New:

- Grade Transparency: For each attribute, defect group, or checklist item, you’ll now see exactly which tolerance, threshold, or standard triggered the result, whether Pass or Fail.

- Inline Explanations: Click on any grade in the report to reveal a tooltip with the detailed logic behind it. This applies to:

- Attribute grades

- Defect group grades

- Individual defects

- Checklist items

- Strict Standard Support: Grading logic is available for inspections conducted using strict specs.

- Consistent for All Stakeholders: These explanations are visible in both internal and public-facing reports.

- Multilingual Display: Reports maintain consistent structure and logic in supported languages, including Spanish.

With transparent grading logic, growers and partners can understand outcomes instantly, minimizing follow-up questions.

See our help center article on smart QC reports with clear grading logic

Customize how total defects are calculated

Some defects matter more than others. Now, you can decide exactly which ones contribute to your total defect score, so your reports reflect what truly impacts product quality—and ignore what doesn’t. toward the final grade. Now, you decide which defect groups affect your total defect score.

What’s New:

- Selective Aggregation: Use the new “Aggregate to total defects” setting to include or exclude specific defect groups from your overall defect score.

- Tailored Reporting: Defect groups used only for documentation or internal tracking can be excluded from summary stats.

- Global or Granular Control: Settings apply across all produce types by default, but can be adjusted per defect group as needed.

This update helps you align quality reports with your operational priorities, without inflating defect totals with issues that don’t impact grading.

See our help center article on flexible total defect calculation

Batch inspections: now available for all users

Whether you’re managing dozens of pallets or tracking containers across a supply chain, grouping inspections is critical. Batch inspection is now available for all Clarifresh users, giving you a powerful way to structure related inspections while keeping workflows organized and auditable., trackable groups. Batch inspections are ideal for high-volume environments—and they’re now available to everyone.

What’s New:

- Hierarchical Inspection Flows: Organize inspections using a two-level structure:

- Parent Batch Process: Capture top-level data (e.g., truck details, arrival time, temperature).

- Child In-Batch Processes: Record inspection details for each item in the batch (e.g., pallet quality, defects, attributes).

- Flexible Grouping: Handle single-produce or mixed loads—batch processes work across any commodity or custom setup.

- Visual Organization: Use the sidebar view to navigate between batch and in-batch inspections with ease.

- Streamlined Reporting: Customize how batch and child data appear in QC reports using saved templates and column settings.

This update brings powerful inspection structuring to all Clarifresh users—ideal for warehouse, distribution, and receiving environments where inspection volumes are high and traceability is essential.

See our help center artilce on batch processes.

Watch the recording or get in touch

Questions? Ideas? Feedback? We’d love to hear from you. Reach out to your account manager or contact our support team.

Thanks again for being part of the Clarifresh community.