AI quality control in fresh produce supply chains is becoming less of a future ambition, and more of a daily necessity.

You’ve checked the same pallet three times: once to train a junior, once because lighting made the defect call uncertain, and once more to be sure. The truck’s waiting. Your inbox is piling up. And you still don’t know if that shipment meets every customer’s spec.

This is the daily tightrope walk of a quality manager forced to rely on subjective visual inspections conducted unforgiving timelines. In this world, human error in food inspection is inevitable, and costly.

The right mix of AI vs human inspection creates a new kind of quality operation: one where computers handle the repeatable tasks, and humans lead with judgment, oversight, and strategy.

But what does that actually look like in the real world? And how do you separate the hype from the practical?

In this blog, we’re providing answers, and taking a look at what hybrid QC systems look like in fresh produce organizations around the globe.

Why Quality Control in Produce Is So Critical

According to the USDA, more than 30% of fruits and vegetables are lost post-harvest. That’s not because of supply shortages or transport breakdowns, but because of quality control gaps.

So how exactly does quality control impact waste?

Export-Readiness Depends on QC

In fresh produce, quality is the gatekeeper to export readiness, shelf-life optimization, and consumer confidence. One missed defect, one misjudged ripeness level, and an entire shipment can be rejected, costing growers and exporters both money and reputation.

But Traditional QC Methods Can’t Keep UP

As global markets demand ever-stricter standards, traditional inspection methods that rely on the human eye and paper logs are struggling to keep pace. Human error in food inspection can mean the difference between premium-grade fruit that ships and borderline cases that don’t clear customs.

And Consumer Expectations Keep Rising

Even in domestic markets, quality inconsistency eats away at brand trust. Retailers don’t just want fresh. They want real-time freshness scoring, predictable shelf life, and proof that your process can scale with demand.

That’s why the shift toward automated quality control systems and computer vision for produce grading is about much more than convenience. It’s increasingly key to survival in a market where the bar keeps rising.

Human vs. AI-Based Inspection: A Side-by-Side Comparison

When it comes to quality control, both human judgment and AI have strengths. But they perform very differently under pressure. The table below breaks down how traditional methods stack up against AI quality control in fresh produce, especially in high-volume, high-stakes environments.

| Attribute | Human QC | Clarifresh AI QC |

| Speed | Slower, varies by workload and inspector availability. | Instantaneous per item via an automated quality control system optimized for high-volume environments. |

| Accuracy | Inconsistent, affected by fatigue, lighting and experience. | 95%+ defect detection and accuracy with computer vision for produce grading and deep learning models for quality control. |

| Scalability | Limited by team size and training bandwidth. | Easily scales across sites and regions, consistency output regardless of volume. |

| Objectivity | Subjective assessments, risk of inconsistent standards. | Standardized, algorithm-driven evaluations ensure consistency in grading fruits and vegetables. |

| Cost | Ongoing labor costs, training, and reinspection time. | Cost-efficient long-term with reduced waste, fewer rejections, and faster throughput. |

What Is Clarifresh and How Does It Work?

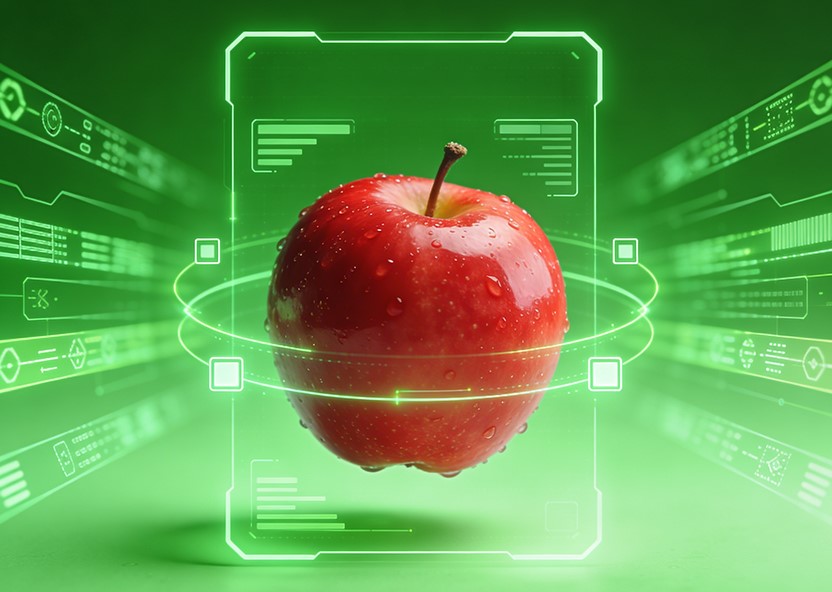

Clarifresh ensures consistent, unbiased, high-speed inspections using proprietary machine learning and computer vision models. Designed specifically for the complexities of fresh produce, Clarifresh combines AI fruit inspection with practical tools that support real-world workflows in the field, packhouse, or warehouse.

At its core, Clarifresh uses computer vision for produce grading, capturing detailed visual data on color, size, shape, and surface defects in real time. This is enhanced by deep learning models for quality control that have been trained on thousands of images across diverse crops and growing conditions.

But the benefits don’t stop at automation. Clarifresh also supports manual overrides, so experienced inspectors can adjust grades or flag edge cases when needed. All decisions (AI or human) are logged and traceable, creating a transparent record for real-time freshness scoring, reporting, and compliance. This hybrid flexibility makes it easy for teams to transition from traditional methods without losing oversight or control.

Whether you’re inspecting in the field or at a retail depot, Clarifresh gives your team the tools to make faster, smarter calls grounded in data, not just instinct.

Q&A: Clarifresh AI and Quality Control

Can AI detect internal defects in fruits or vegetables?

While traditional computer vision systems rely on external appearance, some advanced solutions — including those using hyperspectral imaging or NIR (near-infrared) — can detect internal quality issues such as bruising or rot. Clarifresh currently focuses on high-confidence surface-level defect detection but can integrate with sensor-based tech for deeper QC.

What kind of training data does Clarifresh use?

Clarifresh trains its models on millions of real-world produce images, labeled by quality inspectors across global regions. This creates a model tuned to commercial-grade definitions of ripeness, defects, and shelf life indicators.

How is bias handled in AI inspections?

Bias is reduced by feeding the model diverse training sets from multiple regions and seasons. Unlike human inspectors who may apply inconsistent standards, Clarifresh ensures uniform grading criteria across sites.

What produce types does Clarifresh currently support?

Clarifresh works with major commercial fruits and vegetables including apples, avocados, tomatoes, cherries, citrus, and leafy greens. Support for tropical and exotic produce is expanding based on client demand.

Can AI inspections meet USDA or export certification standards?

While AI isn’t yet a formal USDA certifier, Clarifresh grading aligns with USDA and Codex Alimentarius standards, and can generate inspection records for audit/compliance purposes.

What happens when the AI is unsure or flags a borderline case?

The system can be configured to either auto-reject borderline produce or escalate to a human override, creating a hybrid flow where accuracy meets human context.

Does Clarifresh work offline or in low-connectivity environments?

Yes. Clarifresh systems are edge-compatible and can run on-device processing in packhouses or fields, syncing with the cloud when bandwidth allows.

How long does it take to train the model on a new product line?

Depending on volume and annotation quality, a new produce line can be onboarded in 2–4 weeks with active labeling and client collaboration.