Meeting Export Compliance with AI-Driven Quality Control

- Quality Control App

Exporting fresh produce is a high-stakes game. One quality lapse—like improper grading, hidden defects, or traceability gaps—and your shipment could be rejected, triggering costly recalls and eroding buyer trust. In fact, U.S. farm-level compliance with the FDA’s Produce Rule can cost small farms as much as 6–6.8% of annual sales revenue.

For exporters, manual inspections simply don’t cut it. As export volumes rise and regulations tighten globally, AI-powered produce quality control offers exporters a competitive edge.

In this blog, we’ll explore how Clarifresh AI helps exporters meet compliance requirements, prevent costly produce recalls, and safeguard their brand reputation worldwide.

Global Compliance Frameworks for Fresh Produce

Exporters operate within a complex web of international standards that dictate how fresh produce must be graded, packaged, and documented. This section breaks down the key compliance frameworks in major markets, highlighting what’s required to ensure shipments pass inspections without delays or rejections.

European Union (EU)

- General Food Law (EC Regulation 178/2002) enshrines food safety from farm to fork and mandates traceability and rapid-alert systems like RASFF.

- Marketing Standards: For key crops (e.g., apples, citrus, tomatoes), conformity with size, quality, and labeling rules is mandatory, and conformity certificates required.

- Plant Health & Residue Control: Phytosanitary certificates and strict controls on pesticide residues are enforced.

United States (US)

- FDA’s FSMA Produce Rule: Fosters preventive controls, requires farm-to-table traceability, and grants mandatory recall authority for unsafe produce.

- PACA Good Delivery Guidelines: Provide allowable defect rate thresholds (e.g., 10% average defects, with 5% serious damage) for exported produce that lacks specific U.S. grade standards.

Australia

- Export Control Act 2020 & Export Control (Plants and Plant Products) Rules 2021: The primary legislation governing plant product exports from Australia, requiring that all shipments meet prescribed quality, safety, and packaging standards before export certification is granted.

- FSANZ Primary Production & Processing Standards (2025 update): New rules introduced in February 2025 for berries, leafy vegetables, and melons, placing greater emphasis on hazard control, hygiene, and full traceability across the supply chain.

How AI Transforms Compliance from Reactive to Proactive

1. Consistent, Standards-Based Grading

Clarifresh AI applies consistent grading rules aligned with EU classes or USDA defect tolerances. Unlike humans, AI doesn’t fatigue or deviate. You can count on your shipments meeting international specs time after time.

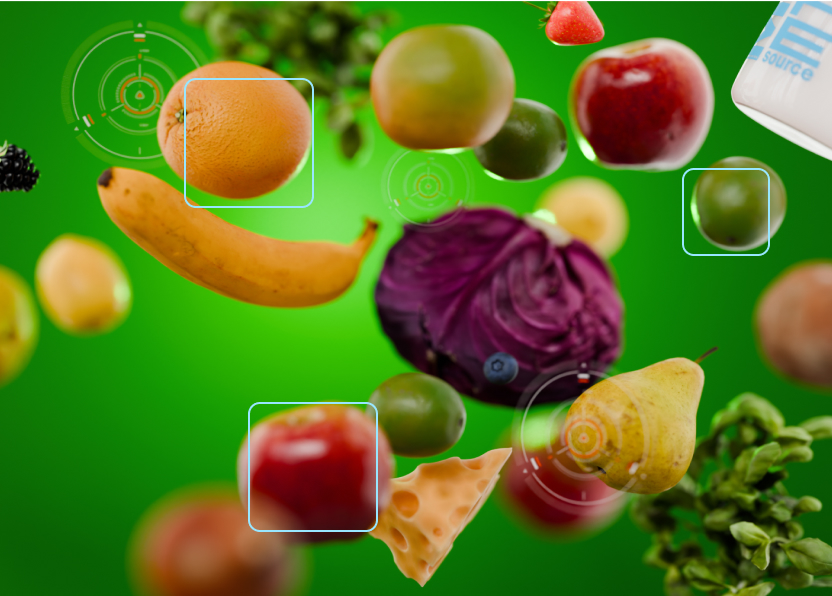

2. Instant Defect Detection & Alerts

Rather than waiting for quality issues to spiral, Clarifresh flags bruises, blemishes, or size mismatches in real time. Early intervention saves entire pallets from being downgraded or rejected.

3. Automated, Audit-Ready Documentation

Each inspection is time-stamped, geo-tagged, and digitally logged—including batch numbers and compliance metrics. This creates a robust, ready-for-audit record that supports recall risk prevention.

Benefits: Reduce Produce Recall Risk & Protect Your Brand

- Fewer Rejections at Destination: By catching defects early, exporters reduce the chances of shipment refusal or costly rework.

- Faster Customs Clearance: Compliant, well-documented shipments move more swiftly through border checks.

- Stronger Brand Reputation: Consistent quality across markets reinforces buyer confidence and protects brand integrity.

- ESG Impact: Reducing rejected produce supports waste reduction and sustainability goals.

Clarifresh AI Features for Export-Ready Assurance

Exporters face a moving target of standards, but Clarifresh AI is built to adapt. Its inspection, reporting, and analytics tools are designed not just to meet compliance requirements, but to make them a natural part of your day-to-day operations.

| Feature | How It Supports Compliance & Recall Prevention |

| Mobile Real-Time Inspections | Inspect at field, packhouse, or pre-loading, ensuring compliance before logistics. |

| Customizable Standards | Tailor grading and defect thresholds to match USDA, EU, or specific retailer rules. |

| Traceable Batch-Level Data | Full supply chain transparency supports rapid problem isolation or recall actions. |

| Predictive Analytics | Spot trends (e.g., seasonally high defect rates), preemptively optimize shipping decisions. |

Common Exporter Questions

Can AI replace human inspectors?

Not entirely, no. It augments them. Clarifresh removes subjectivity and speed barriers, enabling QC teams to focus on strategic oversight.

Will it satisfy formal export certification requirements?

Yes. Clarifresh aligns with recognized grading frameworks and its logs support audits, conformity certificates, and traceability validation.

How quickly does it deliver ROI?

Many exporters see reductions in rejection rates and improvements in export compliance within weeks of implementation.

Conclusion: Compliance Without Compromise

Exporting fresh produce doesn’t have to be a gamble. With AI-driven quality control recall prevention, Clarifresh turns complex, multi-jurisdiction compliance into a streamlined, proactive capability. With this solution in place, exporters can ship confidently, reduce waste, and safeguard brand reputation across markets.If you’re ready to simplify compliance, reduce recall risks, and elevate your export readiness, Clarifresh is your partner for assured quality and safety. Book a demo or contact us today.